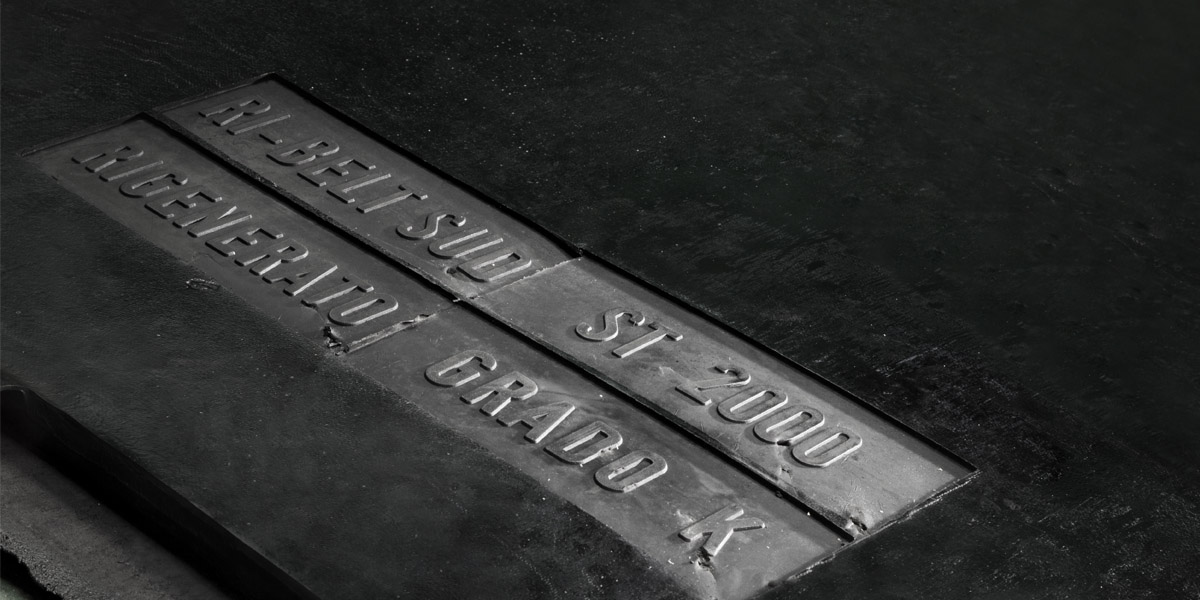

In order to combine the management economy and the ecological requirements against dispose of exhausted waste materials, Ribelt Sud has launched a proper and specifically designed production line for the reconditioning of the used rubber belts on customer’s account. The possibility of reconditioning can be carried out on steel cords reinforced belts with special qualified rubber compounds and strong thick covers.

The reconditioning consists of several stages:

- Inspection and careful check of the condition of the belt and its surface;

- Surface cleaning by means of wire brushes mounted on a machine specially built to remove residues of the transported materials;

- Buffing of both sides by means of a metal milling cutter. The procedure consists of removing residual rubber covers, calibrating the thickness of the belt both in width and length;

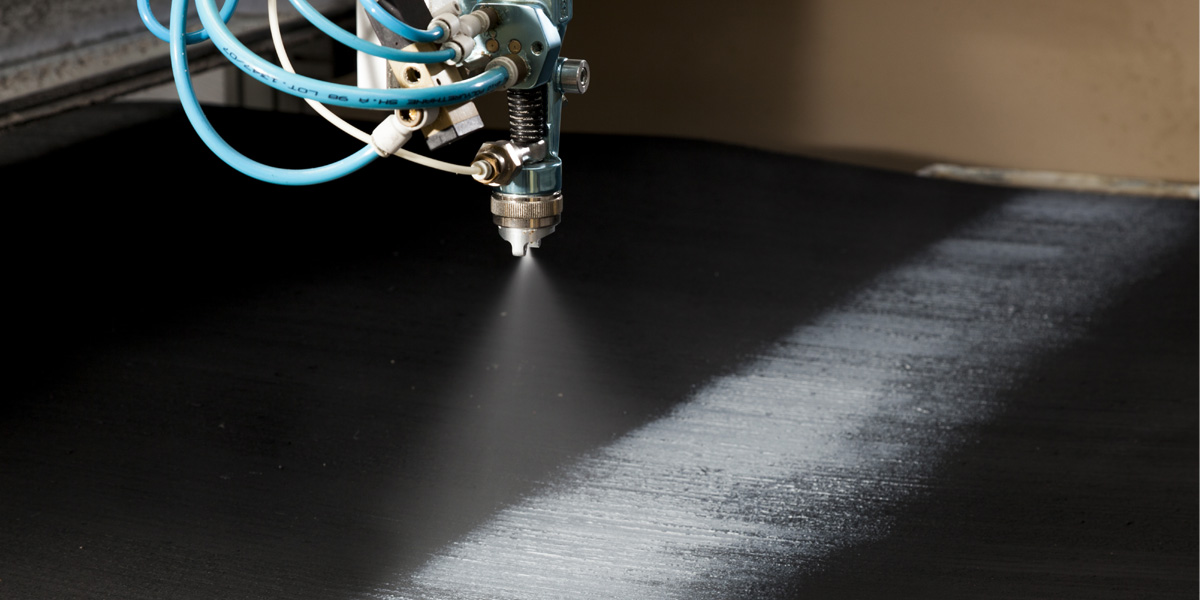

- The roll, repacked as a result of previous operations, is transferred to a special equipment for apply the new raw rubber covers, respecting the original specifications and adherences;

- The hot vulcanization under modern equipped press machines concludes this cycle;

The entire cycle is controlled by a specially designed software, automatically controlling the parameters related to pressure, temperature, vulcanizing and cooling times. Final laboratory tests are made to recheck the belts specifications. The packed roll is suddenly stored and returned to the customer granting the same guarantee period of the brand new belt.